Why people nowadays prefer PCB assembly one-stop service?

This article understands the fundamentals of PCB assembly & explores how the evolution of this industry has reshaped modern manufacturing.

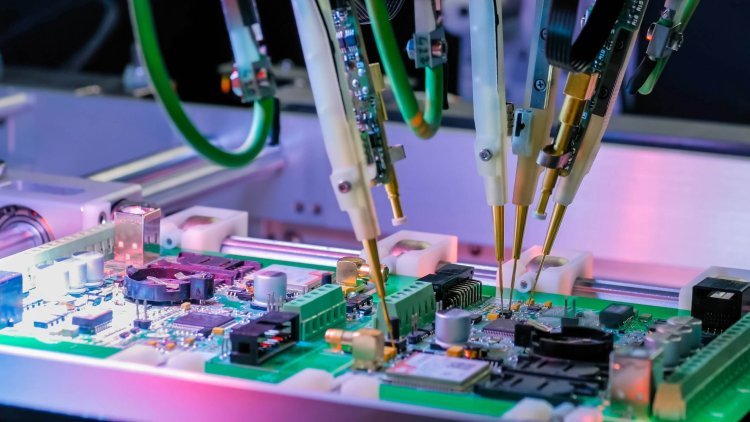

The modern world thrives on innovation, and at the heart of much of this technological growth lies the often-overlooked realm of PCB or printed circuit board assembly. If you’ve interacted with a smartphone, laptop, or even your washing machine today, you’ve already benefited from the marvel of PCB technology. But as the demand for smarter, faster, and cheaper electronics grows, so too does the need for efficient manufacturing processes. Say hi to the PCB assembly one-stop service, a simplified solution that increasingly companies are embracing. Why has this method become the first choice for manufacturers globally?

What is PCB Assembly?

Before we examine the increasing popularity of one-stop services, let's demystify what PCBA entails.

PCBA's essence, fundamentally, is the assembly of electronic parts onto a printed circuit board. A PCB, for its part, is a composite material-thin board that physically supports and electrically interconnects components through conductive paths, pads, and other elements. These electronic components - microchips, diodes, and resistors included- are those responsible for making a device functional by imbuing it with functionality as designed.

But PCB assembly is not a cookie-cutter job. Depending on the design complexity, it can entail many steps, such as:

- Procuring components to get parts required to make the board.

- Applying solder paste to attach components to the board.

- Pick and place assembly, using machines or manual methods to place components.

- Reflow soldering, which applies heat to attach the components firmly.

- Inspection and testing to verify the board functions properly.

These processes require accuracy, professionalism, and huge logistical planning. Historically, businesses have had to deal with several vendors in order to process these phases. However, this fragmented process is gradually being phased out to pave the way for a new darling in the industry - the PCBA one-stop service.

Why People Nowadays Prefer PCB Assembly One-Stop Service?

You may wonder, why is conventional methodology out of favor? It's an approach that has worked for manufacturing for decades. The response is in the inefficiencies that this kind of fragmentation produces - increased risks, more expense, and more potential for mistake.

PCBA one-stop service overcomes these hurdles by integrating all the production stages under a single provider. This system has emerged as a favored option for contemporary companies for a number of strong reasons:

- Efficient Processes Save Time

Time is of the essence, especially in an industry led by fast-changing technologies and consumer needs. Conventional PCBA tends to involve dealing with various service providers - one for design, another for procurement of components, and yet another for assembly and testing.

This configuration is prone to holdups, particularly if a single vendor's timeline conflicts with the rest. A one-stop shop eliminates the holdups that result from differences in vendors' timelines. A one-stop shop performs all its functions under the same roof. The flow of information is improved, processes better harmonized, and projects achieved sooner. It's a breakthrough for startup ventures or entities on tight schedules.

- Cost Efficiency

Although it may sound counterintuitive, bundling services is frequently cheaper. Why? For starters, one-stop providers use their existing networks to buy components in bulk, then pass the savings on to their customers.

Second, having one partner minimizes overheads involved in dealing with many suppliers. Think of the additional labor, logistics, and administrative expenses involved in managing many vendors. Such cost savings, especially for small firms, can be plowed back into innovation or expanding production.

- Minimized Risk of Errors

Picture having to use one vendor for parts, one for assembly, and another for testing. Then picture what could happen when miscommunication exists, or an unforeseen quality control problem is detected at any part of the process. Who finally gets held responsible?

One-stop services lower this risk greatly. Because the whole process - design through delivery - is orchestrated by one vendor, there's built-in responsibility. Errors are spotted earlier, and fixes happen sooner, making for a safety net that avoids expensive interruptions.

- Access to Expertise

One-stop PCBA manufacturers usually have decades of expertise within various aspects of production. This level of experience allows them to provide customized solutions that conventional ways may fail to achieve. Looking for advice on how to optimize your design for manufacturing? Or suggestions for cost-efficient components without compromising quality? A one-stop solution can offer strategic counsel along the way.

Moreover, these providers are innovation leaders. Most of them have top-class facilities, furnished with the best tools and methodologies that enhance efficiency and quality. With such specialists, companies are able to be ahead of their time.

- Seamless Quality Assurance

Product quality is paramount in highly competitive industries. A quality assurance mistake can lead to faulty products, ruined reputations, and losses in revenue. One-stop PCBA services build inspection and testing directly into their process, making sure that every board is up to strict standards when it ships from the factory.

For instance, automated optical inspection (AOI) and functional testing are standard practices in most leading one-stop service hubs. These checks identify issues early, often before they can escalate into bigger problems further down the production line.

- Tailored Solutions for Different Industries

One-stop services offer support to various industries ranging from consumer electronics to automotive, healthcare, aerospace, and more. This flexibility is important as each sector has different challenges and needs. Whether you require high-speed boards for advanced medical devices or industrial automation boards that are tough, one-stop providers develop customized solutions in line with industry norms.

- Support for Start-Ups and Emerging Innovators

Lastly, there's the democratization function of one-stop shops in assisting small players. For start-ups which are not able to afford on-staff PCB specialists or manage an independent supply chain, one-stop shops are a lifeline. They reduce entry barriers, enabling new entrants to realize their ideas without sacrificing quality.

Conclusion

The shift toward one-stop PCB assembly services addresses an industry-wide pattern - big business and small, alike - that is acknowledging the merit in making things simple. By taking complexity and wrapping it into one company, businesses make themselves leaner, better quality, and faster, thereby best positioned to engage in fast-moving markets.

For businesses still finding their way through the transition, it's well worth taking an inventory of your particular needs. What challenges are you dealing with currently in your PCBA? And how could a one-stop shop resolve them? Pondering these questions can help guide you to the appropriate partnership- one that's designed to advance not only your production but also your growth prospects.

What's Your Reaction?