Why Is the Demand for Alternatives to Polyvinyl chloride Packaging Growing?

Introduction

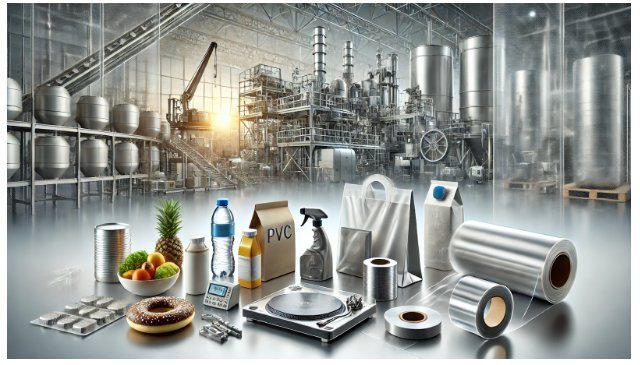

Polyvinyl chloride (PVC) packaging has long been a mainstay in various industries due to its versatility, durability, and cost-effectiveness. From food packaging to medical supplies, PVC is used in a wide range of applications because of its advantageous properties. However, despite these benefits, the demand for alternatives to polyvinyl chloride packaging is growing at a rapid pace. This shift is largely driven by environmental concerns and the increasing desire for more sustainable packaging solutions. In this essay, we will examine the advantages of PVC packaging, its environmental impact, the rising demand for alternatives, and what the future holds for PVC in the packaging industry.

Advantages of PVC in Packaging

Polyvinyl chloride packaging offers several significant advantages that make it a popular choice in various industries. What sets it apart is its sturdiness. PVC carries the property of water and chemical resistance as well as impact resistance which also helps in packing of products for storage or shipment. Furthermore, the material can be made both in rigid and flexible forms therefore, making it suitable for a wide range of products such as shrinkable films, blister packs and bottles.

Another key advantage of PVC is its transparency. This clarity enables consumers to see the product inside, which is particularly useful in retail packaging. Moreover, PVC is relatively inexpensive to produce compared to other packaging materials. Its lightweight nature also helps reduce transportation costs, making it a cost-effective option for many manufacturers.

Environmental Impact and Concerns

While polyvinyl chloride packaging provides undeniable benefits, it poses significant environmental concerns. One of the major issues is that PVC is non-biodegradable. After being thrown away, PVC can last in the surroundings up to many centuries and hence adds to the plastic encumbered landfills and oceans. The accumulation of plastic waste has become a growing concern as more people become aware of the long-term damage caused by these materials.

The challenges of recycling PVC also contribute to its environmental impact. Unlike some other plastics, PVC contains chlorine and other additives, which complicates the recycling process. Many recycling facilities avoid processing PVC because of the potential release of harmful chemicals during recycling. This means that a large proportion of PVC waste ends up in landfills or incinerators, both of which have negative environmental consequences.

In addition, the production and disposal of PVC releases toxic substances into the environment. The manufacturing process involves the use of harmful chemicals like vinyl chloride, a known carcinogen. When PVC is burned, it releases dioxins—highly toxic compounds that can pose serious health and environmental risks. These issues have led to increased scrutiny of PVC packaging and have driven the search for more eco-friendly alternatives.

Alternatives to PVC Packaging

As environmental awareness grows, industries are turning to alternative materials that offer the same advantages as polyvinyl chloride packaging but with a reduced environmental footprint. Another option is the use of biodegradable plastics, which are made so as to disintegrate after a fairly long period of usage.Polylactic acid (PLA), derived from renewable sources like corn starch, is one example of a biodegradable plastic being used in packaging. PLA offers similar properties to PVC in terms of strength and flexibility but has the added benefit of being compostable under the right conditions.

Paper-based packaging is another alternative that is gaining traction, particularly in sectors where sustainability is a priority. Paper is biodegradable, recyclable, and increasingly being engineered to meet the strength requirements of modern packaging needs. Paper-based alternatives can be used for a wide range of products, from food packaging to consumer goods.

Other types of plastics, such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE), are also being explored as alternatives to PVC. These materials are easier to recycle and are less harmful to the environment during production and disposal. PET, in particular, is known for its recyclability and is commonly used in beverage packaging.

Demand for Alternatives to polyvinyl chloride Packaging

The demand for alternatives to polyvinyl chloride packaging is being driven by a combination of environmental concerns, regulatory pressures, and shifting consumer preferences. Consumers are increasingly aware of the environmental impact of plastic waste and are seeking products that are packaged in more sustainable materials. This shift in consumer behavior is prompting companies to look for eco-friendly packaging solutions that can meet these expectations.

Governments and regulatory bodies are also playing a role in the rising demand for alternatives to PVC packaging. Many countries have introduced stricter regulations on plastic waste, including bans on single-use plastics and requirements for increased recycling. These regulations are forcing manufacturers to reconsider their packaging materials and explore more sustainable options.

Furthermore, businesses are recognizing the long-term benefits of adopting sustainable packaging practices. In addition to meeting regulatory requirements and consumer demands, using eco-friendly packaging can enhance a company's reputation and appeal to environmentally conscious consumers. As a result, the demand for alternatives to PVC packaging is expected to continue growing in the coming years.

The Future of PVC Packaging

The future of polyvinyl chloride packaging is likely to be shaped by the increasing emphasis on sustainability. While PVC still has a place in industries where its properties are critical, such as medical packaging, its market share is expected to decline as more sustainable alternatives become available. Innovations in PVC recycling technology could help mitigate some of the environmental concerns, but the overall trend is moving towards reducing the use of PVC in favor of greener materials.

In the years ahead, businesses will likely continue to shift towards packaging materials that are biodegradable, recyclable, or derived from renewable resources. This shift will be driven by both consumer demand and regulatory frameworks that prioritize sustainability. However, PVC may continue to be used in specialized applications where its unique properties are irreplaceable.

Conclusion

The demand for alternatives to polyvinyl chloride packaging is growing due to a combination of environmental concerns, regulatory pressures, and changing consumer preferences. While PVC offers undeniable advantages in terms of durability, cost-effectiveness, and versatility, its negative environmental impact has led to increasing calls for more sustainable solutions. As industries explore biodegradable plastics, paper-based alternatives, and other recyclable materials, the future of PVC packaging will depend on its ability to adapt to the demands of a more eco-conscious world. The rise of sustainable packaging alternatives represents a significant shift in the industry, driven by the need to balance functionality with environmental responsibility.

What's Your Reaction?