Pick and Place - Basics of PCB Design

Making a printed circuit board (PCB) is a key step in manufacturing electronic devices. In this process, SMT pick-and-place machines and PCB design basics play a big role. Understanding these basics is important for beginners.

Making a printed circuit board (PCB) is a key step in manufacturing electronic devices. In this process, SMT pick-and-place machines and PCB design basics play a big role. Understanding these basics is important for beginners. In this guide, we'll look at the basics of PCB design, how to choose and place machines, and tips to help you get started.

1. Basics of PCB Design

Before talking about SMT pick and place machines, it is important to understand PCB design. PCBs are the foundation of electronic devices, connecting different parts through small paths called "traces". Here is a simple overview of PCB design steps:

Step 1: Create a design plan

Start by defining the purpose of your PCB. Determine what components you need (such as resistors, capacitors, and chips) and how they will be connected. Sketch a rough layout of how the parts will be placed.

Step 2: Pick the right ingredients

Choose the right components based on your design. Remember that the SMT pick and place machine will place these parts on the PCB when planning component placement. Choose parts that work well with the machine to ensure easy assembly.

Step 3: Design the PCB layout

Use CAD (computer-aided design) software to create a digital version of your PCB. Tools like Eagle, Altium Designer, and KiCAD let you create and test layouts. The layout shows exactly where each part goes and how each trace connects.

Step 4: Test your design

Testing the layout in your CAD software helps catch any errors early. These tools check electrical properties such as resistance and impedance to make sure everything will work as expected.

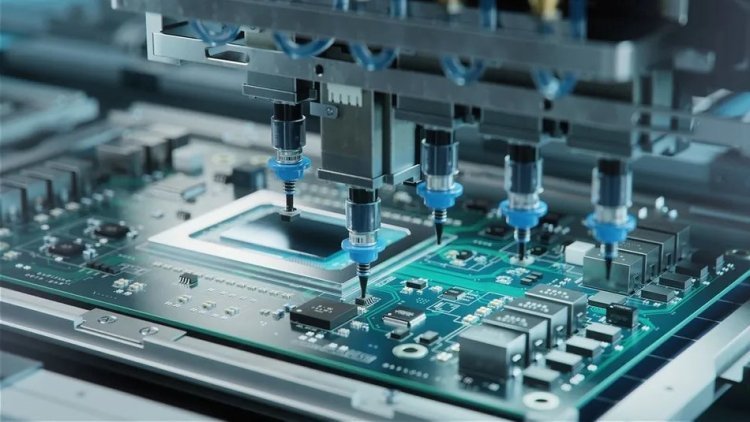

2. What is the SMT pick and place machine?

An SMT pick and place machine is a high-tech device that automatically places small parts on a PCB. These machines are used in electronics manufacturing and make assembly faster and more accurate. With an SMT pick and place machine, small parts are placed on the board precisely and efficiently.

The machine uses a vacuum nozzle to pick up the parts and place them on the board based on the programmed design. It saves time and ensures that every component is perfectly aligned, creating a compact and reliable PCB.

3. Steps to use SMT Pick and Place Machine

To operate an SMT pick and place machine, you have to follow some key steps:

- Set up the program: First, load the PCB design into the machine. You will need a file that tells the machine where each part should go.

- Load feeder system: Parts are placed in a feeder, which the machine uses to pick up each part as needed. The feeder needs to match the design and orientation of the parts.

- Run the machine: Once set up, the SMT pick-and-place machine starts placing the components based on the program.

- Inspect the PCB: After placing all the parts, inspect the board to make sure everything is aligned correctly. Some machines have built-in inspection to detect errors automatically.

4. Choosing the right pick and place machine for your PCB

Not all SMT pick and place machines are the same. They come in different speeds, precision levels, and capabilities. Choosing the right machine depends on what you need, your budget, and how many boards you will be making. For a small project, a basic machine works fine, but for a larger production, a faster, more precise machine is better.

When choosing an SMT pick and place machine, consider:

- Speed: How many parts can it place per minute?

- Accuracy: High precision is important, especially for very small parts.

- User-Friendly Setup: A simple setup and programming system makes it easy to use.

- Component compatibility: Make sure the machine can handle the size of parts you need.

5. Benefits of SMT PCB Assembly Services by Discrete Circuits Company

For larger or more complex designs, working with an SMT PCB assembly service can simplify the process. A company like Discrete Circuits Company specializes in assembling PCBs with SMT pick and place machines and provides reliable, high-quality results. They handle everything from sourcing components to final inspection, making sure your design works as planned.

6. Tips for PCB design with pick and place machines

To get the best results from an SMT pick and place machine, here are some design tips:

- Design for Manufacturing (DFM): Simplify your design to simplify assembly and reduce errors.

- Space Components: Leave enough space between parts so that the pick and place machine can work easily.

- Add fiducial markers: These small marks help align the board in the machine for precise placement.

- Test the prototype first: Before mass production, test the prototype to ensure design and assembly run smoothly.

What's Your Reaction?